Metal Injection Moulding (MIM)

Our process and how MIM works

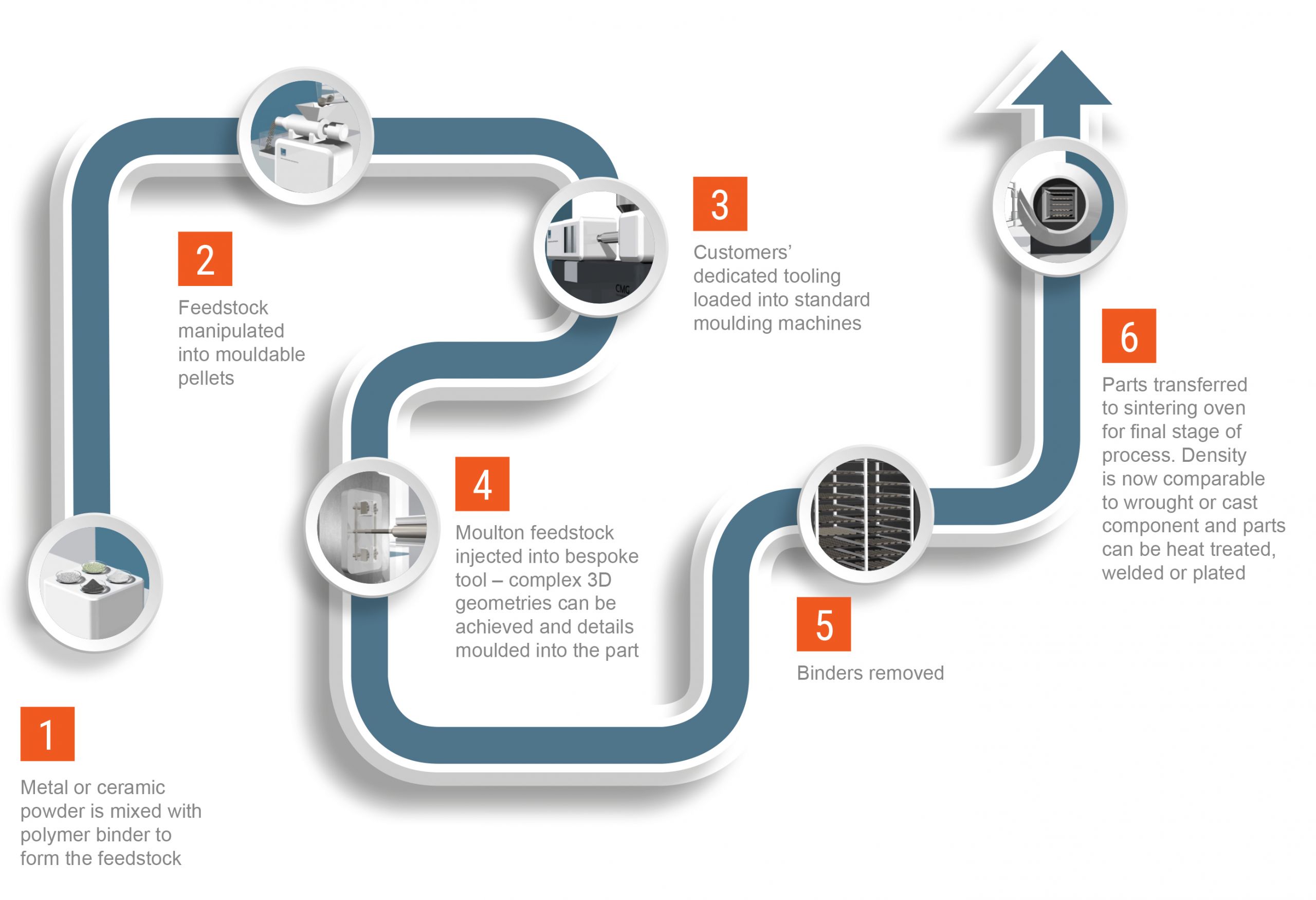

Metal Injection Moulding (MIM) is a manufacturing process that involves manipulating metal powders to behave like a plastic by mixing them with polymer binders to form a feedstock. This feedstock is used to injection mould net shaped, precision components. Parts are then thermally processed to remove the binder system and finally they are sintered to a high density metal component with comparable mechanical properties to wrought materials.

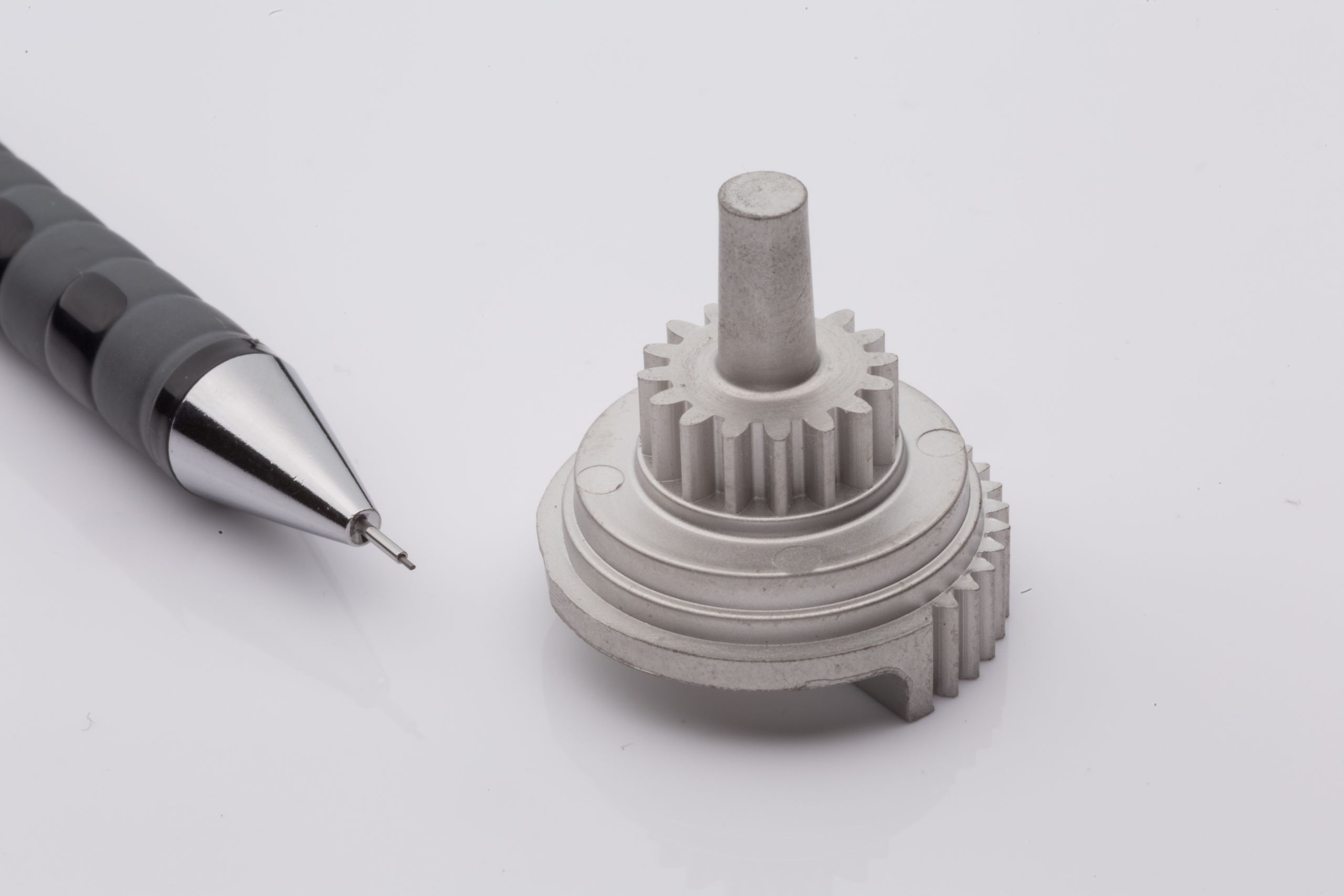

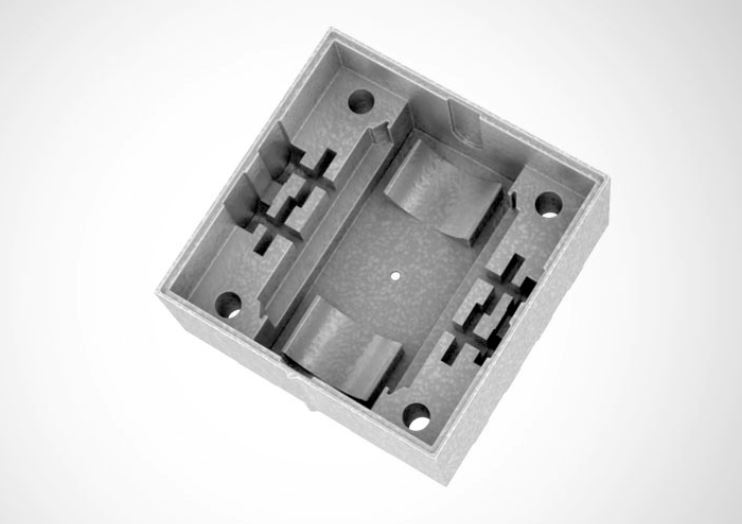

Intricate and complex 3D geometries that in the past have been either very difficult or very costly to produce through traditional manufacturing methods such as 5 axis CNC machining, can be readily achieved with metal powder injection moulding and at significantly reduced prices and lead-times.

Our process

How MIM works

1. Create the Feedstock

Feedstock can be bought as a readymade solution through a Catamould system or mixed in house. Each route has its advantages and CMG offers both options.

The Catamould system is beneficial for larger parts with thicker sections or where a more rapid cycle time is required.

When blending our own feedstock, fine metal powders are mixed with organic binders. This route provides distinctly improved surface finishes, tighter tolerances and better densities as we use finer powders that can be irregular or spherical. A wider choice of materials can also be used.

The ability to tailor the powder to binder ratio controls the shrinkage rate so that we have the option to mould a range of materials within the same tool. This is particularly beneficial when customers want to move existing tooling to CMG, allowing for very short lead-times and avoiding the need for costly tool modifications.

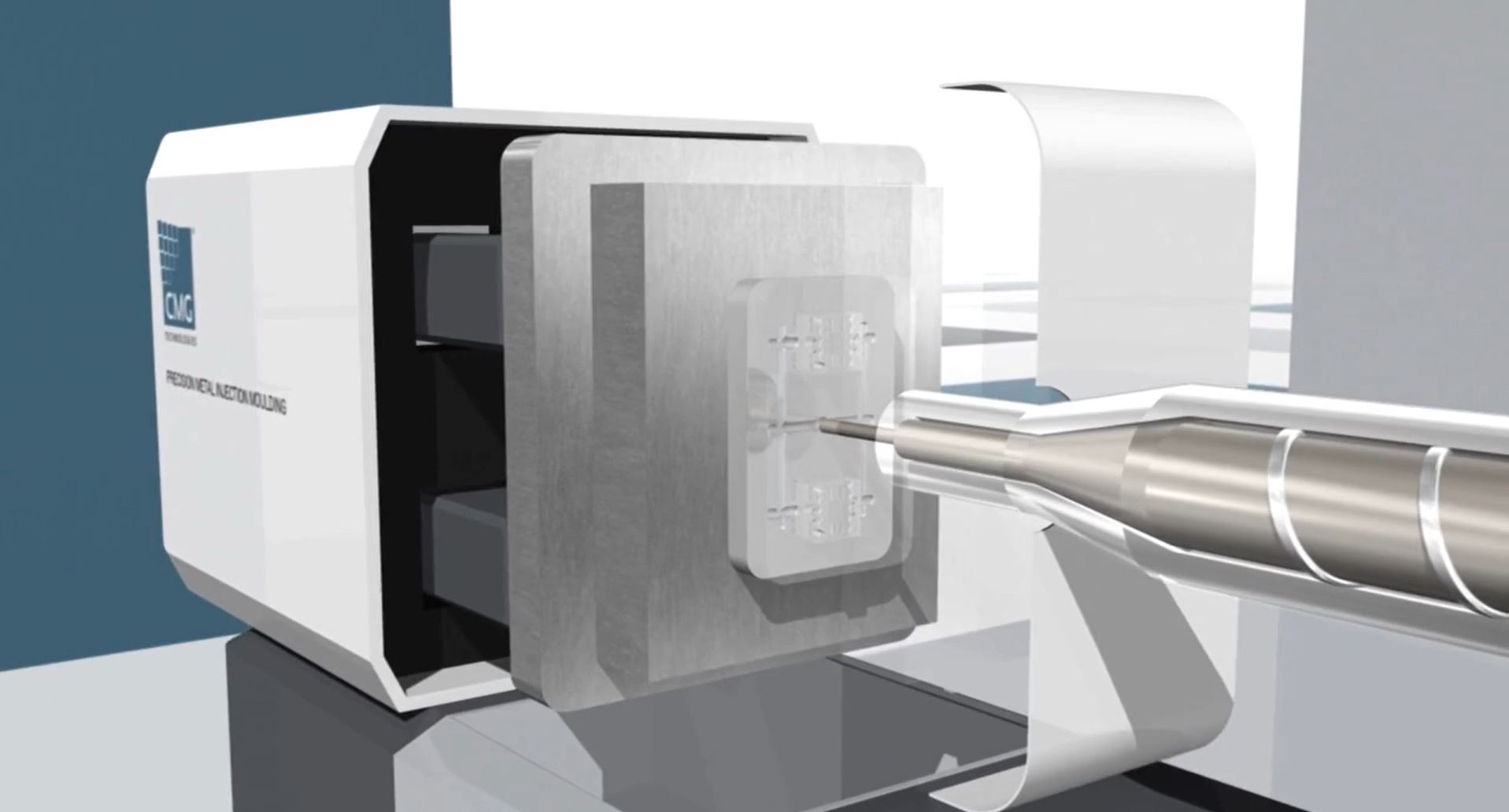

2. Moulding

A custom made tool, designed and produced in-house, is fitted into a standard moulding machine and the feedstock is injection moulded into it to produce a net shaped ‘Green’ component. The knowledge and expertise of our in-house tool department is critical as the quality of the final part is as much dependant on the quality of the tool as it is on the feedstock.

For projects with tight time to market timescales we have the option to produce prototype tooling with shorter leadtimes and reduced costs.

3. De-binding

The moulded ‘Green’ component is transferred to the debind ovens where they are either thermally or solvent debound. Once debound the parts are very brittle and porous as only one binder remains, at this stage parts are referred to as a ‘Brown’ component.

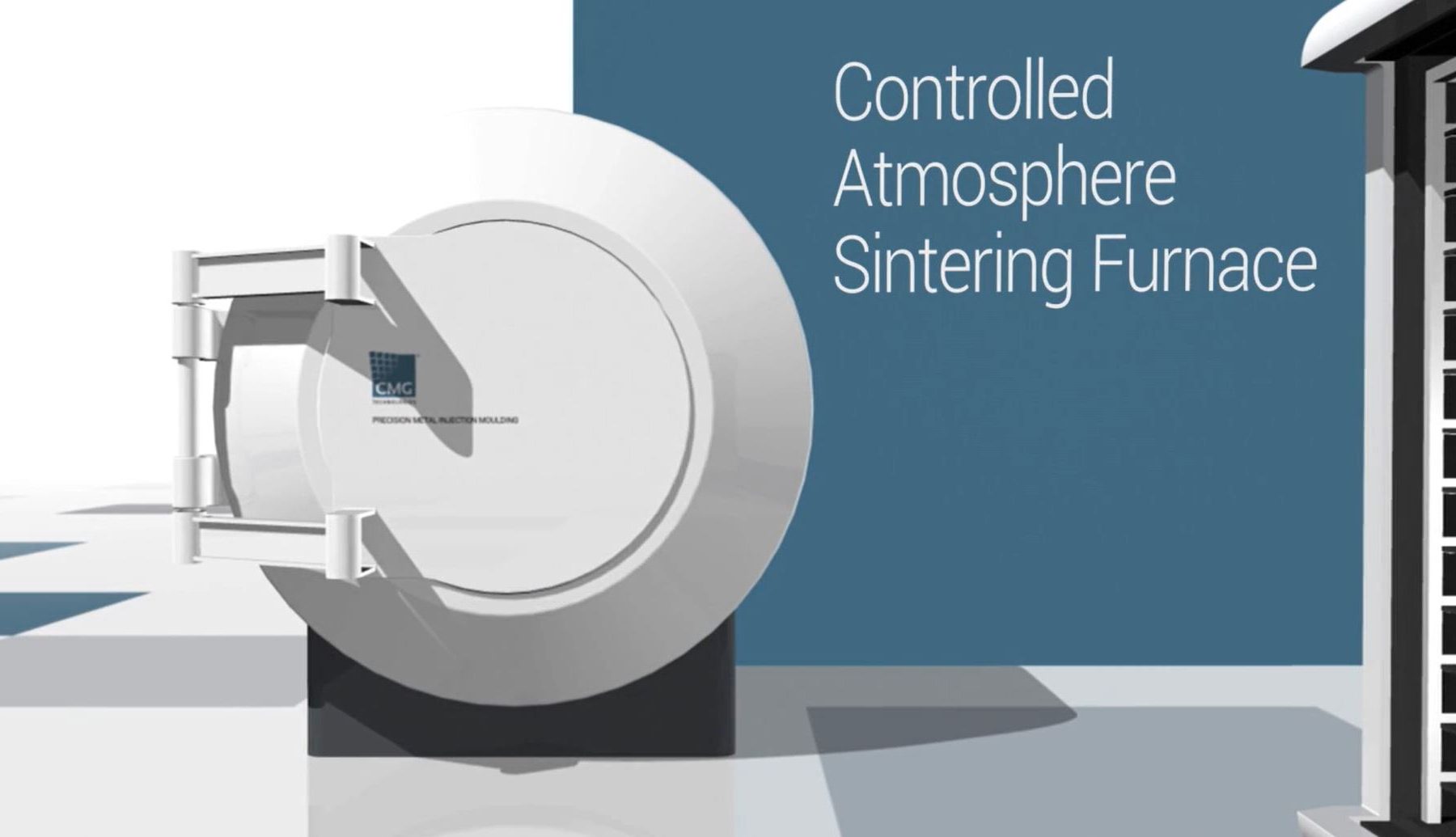

4. Sintering

The ‘Brown’ component then reaches the final stage of the process where it is sintered in a controlled atmosphere. Temperatures are taken to just below melting point of the material, allowing menisci to form between the particles. Controlled, uniform shrinkage of on average 17% occurs at this stage and the component densifies to its finished size, shape and tolerance parameters.

After sintering, the high density ‘White’ component has equivalent properties to wrought materials and can be heat treated, polished, plated or welded.

5. Post sintering operations

CMG’s experience and attention to detail enables us to produce quality precision components that don’t require costly secondary operations. Parts are accurate to +/- 0.5% of a dimension. However, if requirements do exceed even our process capabilities, we work with our clients to develop the most cost-effective solution.