Problem:

Bob Foyers shoots tethered, a process of connecting a camera to a computer displaying photos as they are taken. However, Bob wanted to keep his cables tidy but found his trusted tripod wasn’t suitable for his new TetherBlock.

Loyal to his Manfrotto tripod, Bob tried a same-brand plate but wasn’t confident with its strength. So, he needed to find a new way to fit a cable block to the tripod’s ball head.

Solution:

After photographing CMG Technologies’ products for some years, Bob grew familiar with high-quality engineering. So, he sought the expertise of our Head of 3D Printing, Dr Samuel Wilberforce, who was able to find a solution.

Summary:

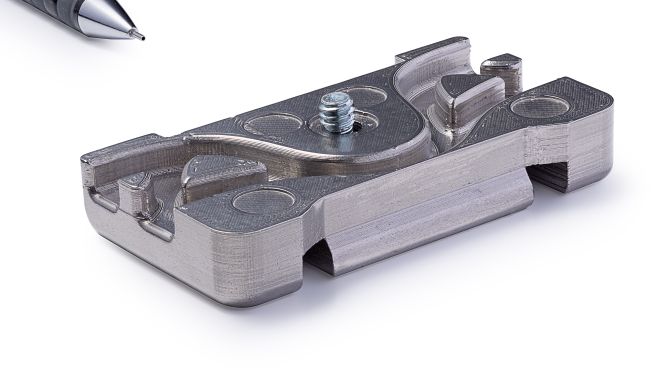

CMG Technologies worked with Bob to find a 3D computer-aided design (CAD) file to use as a base for the part. Unfortunately, it was quickly apparent that the cable block still wouldn’t suit the tripod’s ball head. But a solution was found just as quickly. Using a combination of measurements from the original Manfrotto plate and cable block, CMG Technologies created a bespoke part for Bob.

The part was printed using CMG Tech-X 316L stainless steel with an infill of 35%. Therefore, achieving the desired strength to hold professional cameras while remaining lightweight.

Thanks to the flexibility and intricacy of metal 3D printing, a problem many photographers face was easily resolved. Now, Bob can shoot tethered safe in the knowledge he won’t accidently pull on or remove any cables.

And he can continue using the equipment he know and loves.

Case Study:

Bob Foyers is a photographer based in Bentwaters, Suffolk, and owner of Foyers Photography, known for high quality photos in his studio and also out on the road.

While he specialises in commercial photography, Bob’s talents have resulted in many happy clients requiring – from wedding photographs to social media images, pet portraits and more.

For many years he has been valued partner of CMG Technologies, documenting the vast range of parts created by MIM and metal 3D printing. His images can be found in our gallery.

Bob Foyer, of Foyers Photography, said:

“As a professional photographer, I’m always in search of cutting-edge solutions to improve my work. Recently, I had the pleasure of collaborating with CMG Technologies Ltd, a company based in Bentwaters. Not only did they come to my aid, but they also provided me with a remarkable solution that surpassed my expectations.

“CMG Technologies is a renowned name in the field of Metal Injection Moulding and 3D metal printing. Their expertise is something that I can attest to, after experiencing their excellent work first-hand. You see, I was struggling with a pesky problem: the cable block I used simply wouldn’t fit my tripod head. It was quite the predicament, but thankfully, Samuel from CMG came to my rescue.

“With a keen understanding of my requirements, Samuel promptly designed and 3D printed a stainless steel tether block and tripod plate combined. The result? A seamless fit that has made my photography work a whole lot smoother. To say that I’m delighted would be an understatement.

“Moving forward, I look forward to doing a lot more business with CMG Technologies. Their innovative approach, coupled with their unwavering commitment to customer satisfaction, truly sets them apart. So, if you’re in need of top-notch Metal Injection Moulding or 3D metal printing services, I wholeheartedly recommend giving CMG Technologies a try. You won’t be disappointed!

“I’m ever so grateful for the fantastic work CMG did. As a photographer, it’s crucial to have reliable partners that can provide unique and efficient solutions. And with CMG Technologies, I’ve found just that. Hats off to them!”