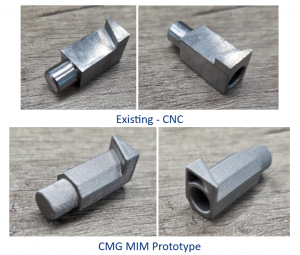

Problem:

Our client required cost-effective slide pins for cantilever applications compared with their existing CNC machined zinc coated pins, which require a significantly higher cost.

Solution:

We 3D printed prototype parts using CMG Tech-X 17-4PH stainless steel filament, which outperformed the zinc alternatives at a fraction of the cost.

Summary:

The prototype slide pins were printed on the side for maximum uniaxial strength in the direction of the applied load.

They were put to the test at our client’s facility and were able to pull approximately 3 tons without the slide pins rupturing.

As well as matching the strength of zinc, the stainless steel filament also meant the parts have high temperature capability, better overall dimensional control, a clean surface finish and a lower risk of corrosion.

It also eradicated the need for parts to undergo a zinc galvanising process.

What the customer had to say:

“The CMG prototype components underwent testing at our facility as part of our product development testing. The prototypes were able to achieve all functional requirements at a reduced part cost.

“We pulled nearly 3 tons on the shear test and the bracket itself started to tear. The pins were still intact.”