3D metal fused filament fabrication (FFF) printing offers infinite opportunities for businesses – with small, intricate parts being used to run some of the world’s biggest and most exciting pieces of machinery.

But with so many different parts on offer, you might be wondering to yourself – what kind of products do CMG Technologies create? Here, we break down our 3D FFF printing applications into three broad areas and look at how they help make our clients’ visions a reality.

Functional Prototypes (FPs)

The first type of 3D FFF printing products we create aren’t actually designed for 3D printing at all. Instead, they give us and our clients insight into creating metal injection moulding (MIM) parts.

Creating prototypes using FFF allows our clients to make critical decisions on things like tooling investment at a fraction of the cost. That means we can create small, bespoke parts at a low price and perfect them before we move into MIM production.

An example of this includes a recent tooling investment by London-based client Raaft, who needed approximately 15,000 316L stainless steel blinds produced per year. Our FFF prototyping service allowed us to fine-tune the product ahead of production to great success.

- Raaft’s 3D metal FFF printed 3161L stainless steel FB blinds

- MIM 316L stainless steel blinds

Bespoke Parts (BPs)

Many of our clients turn to us to 3D print parts that cannot be sourced elsewhere.

Typically, that is because the products have been phased out, or simply that they are too expensive to produce via processes such as CNC machining. 3D FFF printing on the other hand is much more cost effective and is growing in popularity.

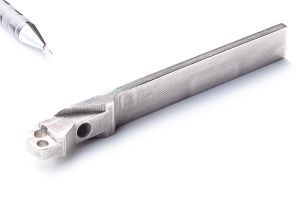

A recent example of this is our work with Rockford, producing functional and lightweight BAND-IT installation handles to meet their needs.

- Rockfords lightweight 3D metal FFF printed 316L stainless steel BP part

- BP part in use

Production Parts (PPs)

Just like with bespoke parts, many businesses turn to us to help source part quantities (typically between one and 100 parts) in a more economically viable way than MIM.

These parts can be used for a whole host of different products – including our 17-4PH stainless steel Safety-of-Life-at-Sea (SOLAS) gas cable connectors for our client Williams Jet Tenders.

These parts are used across their fleet on SOLAS-certified boats, demonstrating how easy and cost-effective it can be to produce such intricate parts using 3D FFF printing.

Williams Jet Tenders 3D metal FFF printed 17-4PH stainless steeel PP SOLAS gas-cable connectors for use in SOLAS-certified boats.

Ready to unlock the potential of 3D FFF printing?

If your business is in need of a cost-effective solution to parts shortages, or you need a bespoke product to be designed – CMG Technologies are here to help.

Contact our expert team today to learn more.