The 21st century has seen 3D printing enter the mainstream with a boom – with businesses, artists and hobbyists all able to access the technology at a relatively low cost.

But aside from the fun of making trinkets, gadgets and gizmos, the technology has advanced in a way that can bring significant benefits to businesses.

Here, we look at the history of 3D printing – and how businesses can use it as an alternative to their current manufacturing methods.

How has 3D printing progressed?

3D printing has its roots in 1980s Japan, where Dr Hideo Kodama invented a rapid prototyping machine that uses a resin to create parts layer by layer.

Various other inventors and patents followed before Scott Crump introduced the world to fused filament fabrication (FFF) – a method of 3D printing that we still use here at CMG today.

Advancements in the technology continued in the 1990s and 2000s, when printers first became commercially available. That boom saw 3D printers sold worldwide – or should we say galaxywide, after astronauts at the International Space Station printed the first ever tool in space.

How can 3D printing benefit businesses?

The FFF method of 3D printing and the advancements it has seen in recent years make it a great choice for businesses looking for low volume production of parts.

This is especially true when prototyping part designs, offering efficient, relatively low-cost options within impressive time scales. This gives product designers the opportunity to conduct functionality and validation testing during the part design stages.

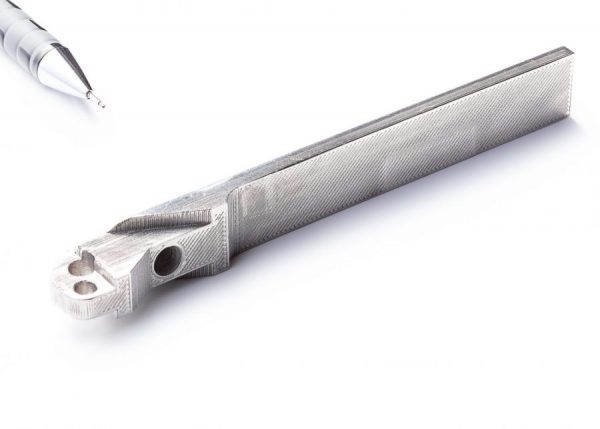

Unlike the 3D printers many now use at home producing primarily thermoplastic 3D prints, FFF allows us to combine polymer binders with metal powders to create filament which is used to produce durable and intricate products in a range of metal alloys at a fraction of the time and cost of most other manufacturing methods.

Those products could be anything from prototypes to integral parts for large-scale machinery – whether that’s just the one component or an order of 1,000. Examples have included safety razors, boat impellers and mountable cable blocks for cameras.

What’s more, the process is also sustainable – with minimal waste produced and emissions kept to a minimum.

Metal filaments we use at CMG include 316L stainless steel, 100Cr6 hardening steel, copper and Inconel 625 – which all boast unique properties such as corrosion resistance, high tensile strength and heat resistance.

How can businesses use 3D printing?

Businesses looking to unlock the benefits of 3D printing can look no further than CMG and its expert team.

We have built a global reputation for our quality and expertise – and are happy to take on new projects, no matter how big or small.

Contact our team today to learn more.