Advancements in 3D printing technology has made it an effective method to manufacture a range of parts at scale. And the exciting thing is that the technology is still in its relative infancy.

Here, in the second part of a two-part series, CMG’s Dr Samuel Wilberforce looks at the benefits of 3D printing in detail.

What is 3D printing?

3D printing is an additive manufacturing technology used to create parts for a wide range of applications. While its history spans decades, it burst into the mainstream in the late 2000s – although many think it is purely used for small scale, plastic projects.

The truth however is exciting advancements in 3D printing technology means we can now manufacture parts using metal filament, unlocking a vast array of possibilities.

Those metal filaments include, but not limited to 316L stainless steel, 17-4PH stainless steel, copper, H13 tool steel and Inconel 625.

What makes 3D printing a great choice for low-volume production

Both 3D printing and MIM share a range of different advantages – and the choice between the two technologies depends on the project.

These benefits include:

Minimal waste

Just like with MIM, if things aren’t quite right at the first attempt during 3D printing, we don’t need to start again from scratch. All of the materials we’ve used can simply be melted down ready to use again, as many times as needed.

The emissions are also very low thanks to the way we can recycle the solvent used in our debinding system.

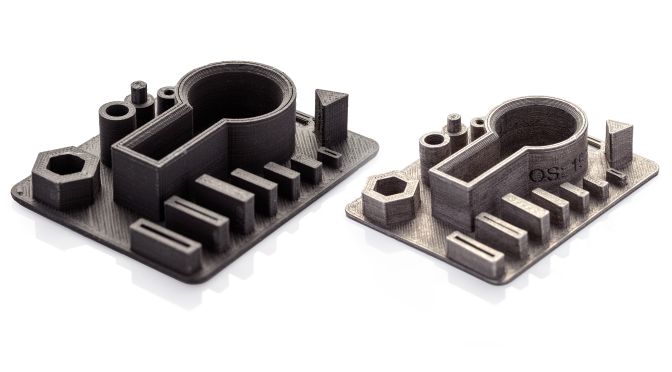

Intricacy

The technology behind 3D printing allows us to manufacture precise and highly accurate parts at relatively small sizes.

And not only does the technology enable us to achieve greater accuracy than certain traditional manufacturing methods, it also does so in a fraction of the time, typically being three times faster to debind than traditional systems.

Lightweight

It is very difficult to make lightweight parts using traditional machining methods – but that isn’t the case with 3D printing. This is because we don’t need to entirely fill the insides of every part we produce and can instead use much stronger internal structures like those you’d see in honeycomb or a lattice.

These parts can even prove both lighter and cheaper than titanium alternatives, all while retaining the same level of strength.

Cost-effective

3D printing comes at a fraction of the costs of traditional manufacturing methods.

Once a design has been approved, our printers can run around the clock to produce items at scale for our clients.

Should I choose 3D printing or metal injection moulding (MIM)?

As our blogs have explored, there are various benefits to both 3D printing and MIM – many of which are shared between both technologies.

In general, the choice between the two depends on the size of a project. If a client requires a high volume of parts, we’d recommend MIM – and on the flipside, for lower volume jobs, 3D printing is generally the way to go.

Our experts here at CMG know the technologies like the back of their hands. If you need support in finding the right method to create parts for your business, contact us today for support.